Pump Repair & Rebuild

Electromechanex

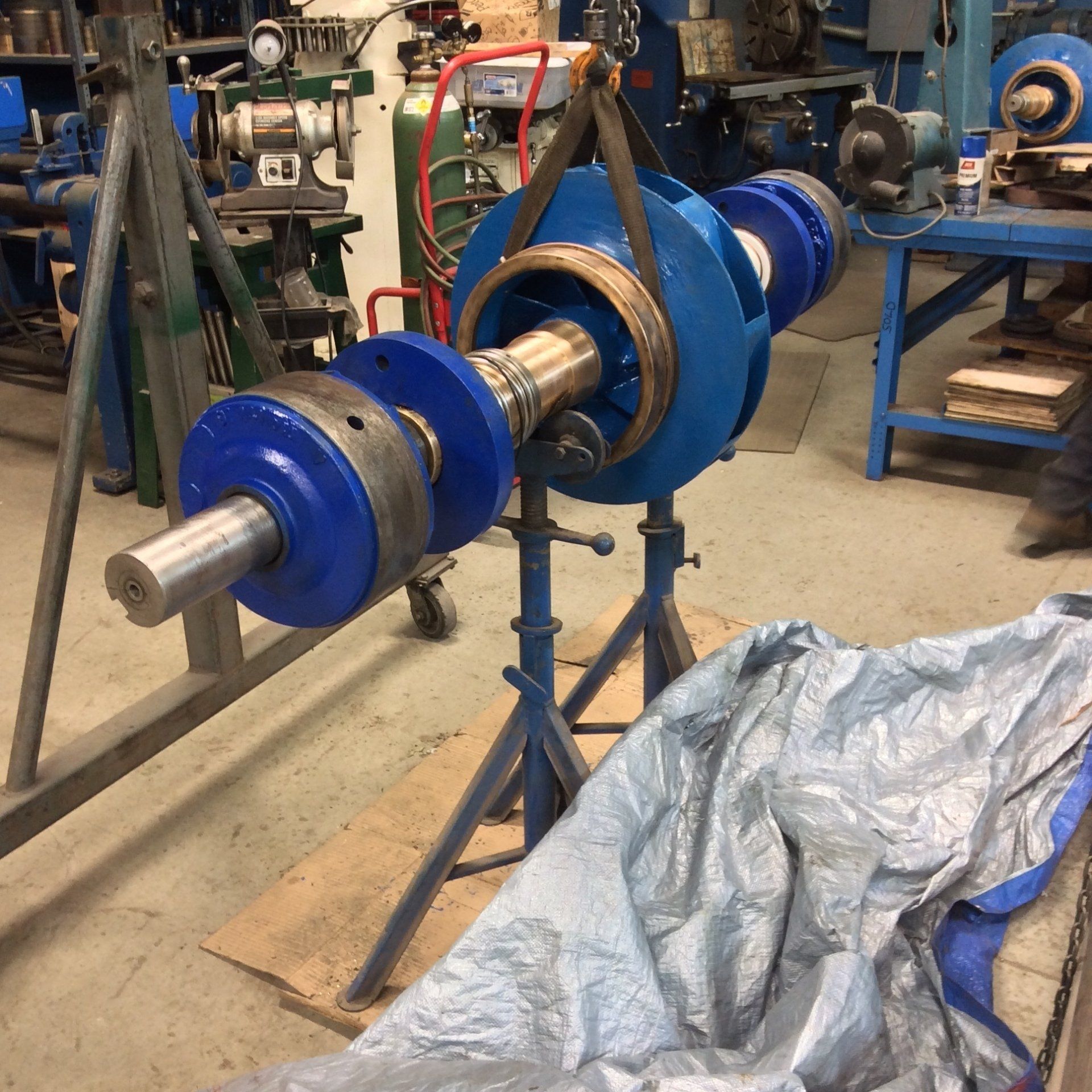

EMX Pump Service offers rebuild, reconditioning, modifications, testing, and maintenance services in the shop and in the field.

Centrifugal Pump Repair and Maintenance services, in the shop and in the field.

EMX Industrial Repair offers comprehensive Pumps repair service and support capabilities include 24 hour service, 7 days a week.

- Vertical Turbine Pumps

- Centrifugal Water Pumps

- Split Case Horizontal Pumps

- Submersible Sewage & Dewatering Pumps

- Booster Pumps

- Chiller Pumps

- Line Shaft Pumps

- Boiler Feed Pumps

- Irrigation Pumps

- Sewer Ejector Pumps

- High Pressure Pumps

- End Suction Pumps

- Fire Pumps

- Swimming Pool Pumps

- ASNI Process Pumps

Pump Repair Capabilities Include:

- Diagnostic and Testing

- Impeller Repair, Rebuilding, Balancing, & Trimming

- Full line of Mechanical Seals & Kits

- Full line of Ball & Roller Bearings

- Preventative Maintenance Programs

- Seal and Bearing Replacement

- Shaft & Impeller Fabrication

- Full Machine Shop

- Electrical & Mechanical Services

- Mechanical Seal Conversions & Installations

- Motor Rebuild & Rewind

- On-site Pump Service

- Cryogenic Pump Repair

- Vacuum Pump Rebuilding

- Pump Retrofits

- Custom Adapter Flanges

Incoming Pump Inspection

EMX Pump Repair Shop performs a thorough appraisal of the Pump’s condition, as received, to determine what specific repairs are needed as well as to find unsuspected trouble, perhaps unrelated to the obvious defect. Our technicians diagnose cause and effect to help prevent a recurrence. The Pump may have been sent to our Repair Facility with limited external evidence as to the nature and location of trouble. What seems wrong may be correctable in several ways. Our appraisal will include a complete review of the following conditions of each part of the Pump: General cleanliness, Cracked or broken welds or castings, Missing hardware, Wear or rub marks, including fretting, discoloration, charring, or other evidence of overheating , Looseness at mating fits, Corrosion, moisture, or oil leaking outside the machine. Digital Photographs of any abnormal conditions found are part of the appraisal process and inspection report. Our Pump Repair includes disassembly, detailed inspections, and measurements to identify mechanical damage.

Disassembly & Inspection

Before any disassembly is begun, parts will be marked (i.e., brackets, frame and covers) Brackets and bearings will be identified as pairs. Check and record rotor air gap. Frame-mounted devices will be identified and recorded. Electrical wiring is recorded, sketched, and marked before disconnecting (for external connection). The condition of the impeller and the extent of repairs are determined by inspection for component wear and process contamination.

Pump components & parts are thoroughly cleaned. Steam cleaning is the preferred method. Shafts will be checked for wear, cracks, scoring and straightness. (NEMA MG 1-2003 Rev.1-2004, Section 1, Part 4 Par. 4.11); cracks, corrosion; scoring or galling. Shaft extensions should be smooth, polished and concentric with the shaft center. Shaft extension dimensions and permissible runout will be checked and Diameter Tolerances for NEMA/IEC frame size machines compared. Keyseat/ Keyway Width Tolerances checked against NEMA/IEC Frame Size machines Tables. Keyseats will be true and accommodate keys to tap fit. If the shaft requires repair, worn surfaces can be restored within our Machine Shop to factory specification. Ball or Roller Bearings (Antifriction bearings) are comprehensively inspected for condition of lubricant; dirt, rust, or moisture; fretting corrosion; thermal discoloration; pitting or spalling of balls, rollers, or races; broken or missing retainers. Sleeve Bearings are checked to be uniform in diameter, of proper fit in the housing, smooth internally and suitably grooved for adequate distribution of lubricant. Bearing Housings and Shaft bearing fits are measured and compared to manufacturer’s specifications. Any fits that are not within tolerance are restored to original factory specification. Seals & Seal clearance are set to original equipment manufacturer’s specifications if available. Oils used will be compatible with the customer’s lubricant. Frame and Bearing Housings will be examined for defects; Corrosion; structural weld integrity; blocked drains, breathers, or ventilating air passages; paralleling of feet. Cracks and breaks are repaired and fits restored to manufacturer’s specifications.

A complete inspection, includes the evaluation of gaskets, valves, temperature probes, belts, couplings, pulleys, and electrical motors, as well as, obvious defects, component wear and process contamination. Working from a complete evaluation report, a service representative will then provide you with a competitive quote and an expected delivery date.

Impeller Balancing

At EMX we take great pride in delivering more than just a repaired component. And we don’t just rebuild to meet OEM specs. EMX Shop Balancing Systems are designed to perform measurements of vibrations and calculations in horizontal shop balancing machines and in the field. The application measures the running speed (1X) filtered vibration amplitude and relative phase with a reference mark in the rotor to allow full balancing correction. Dynamic Balancing results are to be performed to the level G2.5 quality grade (ISO 1940/1) to enable the machine to meet final vibration limits.

Assembly

All mechanical repairs on shafts, bearing journals, end bells, and other equipment are handled in-house by experienced machinists. All Pump assemblies are made in accordance with good machine shop practices. If the shaft requires replacement, a new shaft will be made of A.I.S.I. 4140 Steel HRHT (Hot Rolled Heat Treated). Under special cases, shaft material will be replaced with 316 stainless or User approved material. Pumps will be assembled in a manner that will ensure proper fit and alignment. Ball and Roller Bearings are fitted to shafts by heat-expanding the inner bearing race in accordance with the bearing manufacturer’s recommendations, however, not to exceed 250°F, using an oil-bath heater or an induction heater. Check and record endplay. All bolts, nuts, etc., will be replaced as required with SAE grade 5 or better and torqued to Industry standards. On metric fasteners we will use a grade 8.8 or better. All assembled components will be checked to ensure secure fits. All covers on openings in the frames or housings will be sealed.

Final Testing

EMX also employs the most complete and thorough after-repair test procedures in the industry. We perform bench and system tests to ensure that every repaired pump will operate to factory specification. Every Pump repaired is tested for proper electrical and mechanical operation. Voltage, Current, Bearing temperature, and Vibration are closely monitored and documented. Pumps are Run tested at minimum of 60 minutes duration at the rated voltage and until the temperature of the bearings have stabilized (+/- 1°C over 15 minutes). On antifriction bearings the bearing housing temperature should not exceed 30°F above ambient temperature for oil lubrication, and 50°F above ambient for grease lubrication. On Pumps without external cooling, the bearing housing temperature should not exceed 50°F above ambient. At no time should the temperature exceed the drop test temperature of the lubricant. A non-load test run will be made on all pumps to ensure that all mechanical test results are within factory specification. A written record of all tests and inspection results will be furnished to the user upon completion of repairs.

Completed apparatus will be externally cleaned and painted to specification. Shaft extensions are treated to prevent corrosion.

Packaging and Transportation

After completion of the repair and testing, the machine will be packed in a manner suitable for the form of transport to be used. Packing and transport will be as arranged with the customer. Oil-lubricated machines will be shipped without oil, and the need for lubricant clearly identified.

EMX is a Total Solution Provider. We can handle turnkey project management, from Design to Build to Installation to Ongoing Engineering Support and Maintenance.

Centifugal Pump Services

Precision Installation, Maintenance and Repair Service. Emergency Services are available 24 hours a day, 365 days a year.

- Rotating equipment diagnostics

- Motor Control services

- Online and Offline motor testing

- Laser Shaft Alignment

- Base leveling and grouting

- Machinery installation support

- Preventive & Predictive maintenance

- On Site Equipment Balancing

Vacuum Pump Repair and Maintenance services, in the shop and in the field.

EMX Industrial, repairs and remanufactures Vacuum Pumps, Diffusion Pumps, and Blowers from various manufacturers and numerous types:

- Mechanical Vacuum Pumps

- Dry Pumps

- Wet Pumps

- Scroll Pumps

- Rotary Piston Pumps

- Piston Pumps

- Rotary Vane Pumps

- Vane Pumps

- Industrial Pumps

- Diffusion Pumps

- Positive Displacement Pumps

- Blowers

Vacuum Pump Capabilities Include:

- On-site Vacuum Pump Service

- Vacuum System Surveys

- Vacuum Pump Rebuilding

- Retrofits for Vacuum Pumps

- Automatic Regeneration Controls

- Custom Adapter Flanges

- Impeller & Lobe Balancing

- Preventative Maintenance Programs

- On-Site Leak Testing

- Service Agreements

- Full Machine Shop

- Motor Rebuild & Rewind

Vacuum Pump Repair

Incoming Pump Inspection

EMX Pump Repair Shop performs a thorough appraisal of the Pump’s condition, as received, to determine what specific repairs are needed as well as to find unsuspected trouble, perhaps unrelated to the obvious defect. Our technicians diagnose cause and effect to help prevent a recurrence. The Pump may have been sent to our Repair Facility with limited external evidence as to the nature and location of trouble. What seems wrong may be correctable in several ways. Our appraisal will include a complete review of the following conditions of each part of the Pump: General cleanliness, Cracked or broken welds or castings, Missing hardware, Wear or rub marks, including fretting, discoloration, charring, or other evidence of overheating, Looseness at mating fits, Corrosion, moisture, or oil leaking outside the machine. Digital Photographs of any abnormal conditions found are part of the appraisal process and inspection report. Our Pump Repair includes disassembly, detailed inspections, and measurements to identify mechanical damage.

Disassembly & Inspection

Before any disassembly is begun, parts will be marked (i.e., brackets, frame and covers) Brackets and bearings will be identified as pairs. Check and record rotor air gap. Frame-mounted devices will be identified and recorded. Electrical wiring is recorded, sketched, and marked before disconnecting (for external connection). The condition of the impeller and the extent of repairs are determined by inspection for component wear and process contamination.

Pump components & parts are thoroughly cleaned. Steam cleaning is the preferred method. Shafts will be checked for wear, cracks, scoring and straightness. (NEMA MG 1-2003 Rev.1-2004, Section 1, Part 4 Par. 4.11); cracks, corrosion; scoring or galling. Shaft extensions should be smooth, polished and concentric with the shaft center. Shaft extension dimensions and permissible runout will be checked and Diameter Tolerances for NEMA/IEC frame size machines compared. Keyseat/ Keyway Width Tolerances checked against NEMA/IEC Frame Size machines Tables. Keyseats will be true and accommodate keys to tap fit. If the shaft requires repair, worn surfaces can be restored within our Machine Shop to factory specification. Ball or Roller Bearings (Antifriction bearings) are comprehensively inspected for condition of lubricant; dirt, rust, or moisture; fretting corrosion; thermal discoloration; pitting or spalling of balls, rollers, or races; broken or missing retainers. Sleeve Bearings are checked to be uniform in diameter, of proper fit in the housing, smooth internally and suitably grooved for adequate distribution of lubricant. Bearing Housings and Shaft bearing fits are measured and compared to manufacturer’s specifications. Any fits that are not within tolerance arerestored to original factory specification. Seals & Seal clearance are set to original equipment manufacturer’s specifications if available. Oils used will be compatible with the customer’s lubricant Frame and Bearing Housings will be examined for defects; Corrosion; structural weld integrity; blocked drains, breathers, or ventilating air passages; paralleling of feet. Cracks and breaks are repaired and fits restored to manufacturer’s specifications.

A complete inspection, includes the evaluation of gaskets, valves, temperature probes, belts, couplings, pulleys, and electrical motors, as well as, obvious defects, component wear and process contamination. Working from a complete evaluation report, a service representative will then provide you with a competitive quote and an expected delivery date.

At EMX Electro-Mechanical, we make sure you minimize your process downtime by offering fast turnaround and rental pumps upon request, depending on availability.

Impeller & Lobe Balancing

At EMX, we take great pride in delivering more than just a repaired component. And we don’t just rebuild to meet OEM specs. EMX Shop Balancing Systems are designed to perform measurements of vibrations and calculations in horizontal shop balancing machines and in the field. The application measures the running speed (1X) filtered vibration amplitude and relative phase with a reference mark in the rotor to allow full balancing correction. Dynamic Balancing results are to be performed to the level G2.5 quality grade (ISO 1940/1) to enable the machine to meet final vibration limits.

Assembly

All mechanical repairs on shafts, bearing journals, end bells, and other equipment are handled in-house by experienced machinists. All Pump assemblies are made in accordance with good machine shop practices. If the shaft requires replacement, a new shaft will be made of A.I.S.I. 4140 Steel HRHT (Hot Rolled Heat Treated). Under special cases, shaft material will be replaced with 316 stainless or User approved material. Pumps will be assembled in a manner that will ensure proper fit and alignment. Ball and Roller Bearings are fitted to shafts by heat-expanding the inner bearing race in accordance with the bearing manufacturer’s recommendations, however, not to exceed 250°F, using an oil-bath heater or an induction heater. Check and record endplay. All bolts, nuts, etc., will be replaced as required with SAE grade 5 or better and torqued to Industry standards. On metric fasteners we will use a grade 8.8 or better. All assembled components will be checked to ensure secure fits. All covers on openings in the frames or housings will be sealed.

Final Testing

EMX also employs the most complete and thorough after-repair test procedures in the industry. We perform bench and system tests to ensure that every repaired pump will operate to factory specification. Every Pump repaired is tested for proper electrical and mechanical operation. Voltage, Current, Bearing temperature, and Vibration are closely monitored and documented. Pumps are Run tested at minimum of 60 minutes duration at the rated voltage and until the temperature of the bearings have stabilized (+/- 1°C over 15 minutes). On antifriction bearings the bearing housing temperature should not exceed 30°F above ambient temperature for oil lubrication, and 50°F above ambient for grease lubrication. A vacuum gauge is used to test absolute vacuum pressure and a thermocouple gauge, in conjunction with a given volume (test tank) can be implemented to qualify acceptable pumping speed. A non-load test run will be made on all pumps to ensure that all mechanical test results are within factory specification. A written record of all tests and inspection results will be furnished to the user upon completion of repairs.

Completed apparatus will be externally cleaned and painted to specification. Shaft extensions are treated to prevent corrosion.

Packaging and Transportation

After completion of the repair and testing, the machine will be packed in a manner suitable for the form of transport to be used. Packing and transport will be as arranged with the customer. Oil-lubricated machines will be shipped without oil, and the need for lubricant clearly identified.

EMX Industrial Repair is a Total Solution Provider. We can handle turnkey project management, from Design to Build to Installation to Ongoing Engineering Support and Maintenance.

EMX Vacuum Pump Services

Precision Installation, Maintenance and Repair Service. Emergency Services are available 24 hours a day, 365 days a year.

- Rotating equipment diagnostics

- Motor Control services

- Online and Offline motor testing

- Laser Shaft Alignment

- Base leveling and grouting

- Machinery installation support

- Preventive & Predictive maintenance

- On Site Equipment Balancing